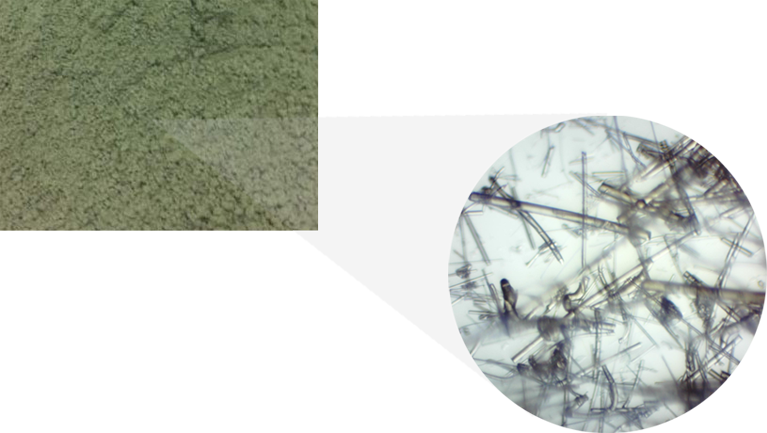

Basalt microfiber

Basalt innovations for you.

Basalt microfiber is designed to create 3D-reinforced composite materials. It is made from mechanically crushed superthin basalt fiber, which is produced by the induction melting of basalt at approximately 2200ºC. This process completely destroys the crystalline structure of the rock-forming minerals in basalt. Using blow heads, the melt is processed in a single step to form superthin fibers (1–3 microns in diameter) with a completely amorphous structure. These fibers exhibit enhanced mechanical strength and flexibility, as well as better chemical and thermal stability compared to E-glass fibers.

The reduced diameter of these fibers significantly increases their specific strength compared to basalt roving with a diameter of 13–15 microns. Visually, the material appears as a fine beige-gray powder, consisting of superfine basalt fiber fragments. The length of the fragments is determined by the method and duration of grinding. The bulk density of the powder, which depends on the degree of grinding, ranges from 1.5 to 2 g/cm³.

The simplest product, marketed under the trademark "MicroBasalt," contains fiber fragments ranging from 25 to 120 microns in length, with 10–20% of fine particles in irregular shapes, measuring 0.1 to 0.5 microns.

We have also developed a technology for separating milled fibers, allowing for the production of MicroBasalt-25, MicroBasalt-50, and MicroBasalt-75 microfibers with average lengths of 25, 50, and 75 microns, respectively. The amount of fine particles (0.1–0.5 microns) in these materials is reduced by about tenfold.

Scope

Basalt microfiber is a nonflammable and environmentally friendly product made from natural raw materials. It has low thermal conductivity and is fully transparent to electromagnetic waves. Its electrical conductivity is lower than that of glass fiber, which enables the creation of high-performance insulating materials for industries such as power engineering, microelectronics, and the cable-conductor industry. The reduced diameter of the microfiber significantly increases its specific surface area, which is beneficial for multiple applications. This increase in surface area makes basalt microfiber an excellent basis for high-performance compact filter materials and also enhances the adhesion between the fibers and the matrix in the production of composite materials.

Basalt microfiber can be used in the production of basalt fiber-reinforced polymer or ceramic composites, resulting in materials with enhanced properties, such as:

- Enhanced mechanical properties: tensile, compressive, flexural, and impact strength;

- Greater durability and abrasion resistance;

- Lower production costs;

- Reduced shrinkage during manufacturing;

- Higher thermal dimensional stability in finished products;

- Capability for grinding and polishing;

- Low electrical conductivity and radio transparency.

Basalt microfiber also serves as an effective reinforcing filler in the creation of protective coatings, gel coats, and repair putties.

Applications of Basalt Microfiber:

- Structural, safety, and power components in the automotive and transport industries.

- Casings for laptops, mobile phones, tablets, and other electronic devices.

- Housings for optical devices: cameras, lenses, tripods, and eyeglass frames.

- Impellers and blades for various applications.

- Armor for tanks, special vehicles, helicopters, and weapon system components.

- Protective coatings and fillers for paints, primers, putties, and adhesives.

- Pipes and gutters for transporting aggressive or abrasive compounds.

- Fabrication of composite rods for 3D printing.

- Designer furnishings and fittings, such as tiles, sculptures, and friezes.

- Reinforcing elements in construction.

- Manufacture of medical devices, including endoprostheses and restorative materials.

- Production of 3D-reinforced polymer films.

- Reinforcement of rubber products, including tires and truck components.

- Power and insulating components in the energy industry.

- Elements of urban and road infrastructure, such as light poles, benches, sewer manholes, and drain grates.

- Fireproof cable boxes, channels, and partitions.

- Sports equipment: rackets, skis, helmets, snowboards, and bicycle frames.

- Tanks for storing and transporting corrosive liquids, including galvanic baths.

- Substrate for next-generation printed circuit boards.

- Manufacture of friction elements, such as high-performance compressor rings with extended service life, lubrication sliding components, and computer coolers.

- Production of antifriction pairs and brake pads.

Products made on the basis of basalt microfiber

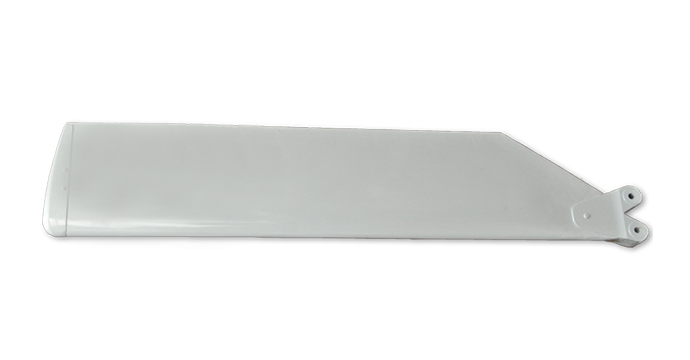

Blade for Wind Tunnel Fan

The blade for a wind tunnel fan is based on modified epoxy resin, reinforced with basalt microfiber. Additional surface reinforcement can be achieved by applying several layers of basalt fabric. Alternatively, a more economical option can be produced using injection molding without the basalt fabric layers.

Mi-2 Helicopter Tail Rotor Blade

The tail rotor blade of the Mi-2 helicopter is constructed using a modified epoxy polymer reinforced with basalt microfiber, with several layers of basalt fabric added for extra strength. The blade is coated with a gray aviation-grade gelcoat for protection and durability.

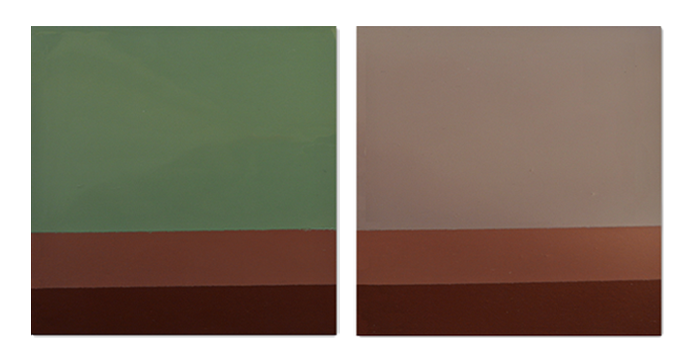

Anti-corrosion coating system

This innovative three-layer anti-corrosion coating system is designed for severe operating conditions (C3–C5, ISO 12944-2). Basalt microfiber, modified with zirconium silicate, is used as a filler for the two lower layers to enhance corrosion resistance.

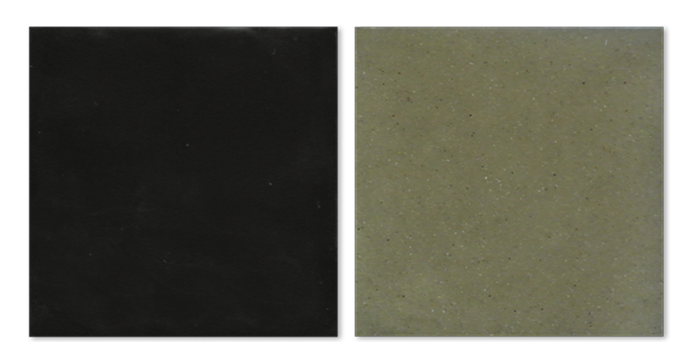

Wear-Resistant Flooring

Polymer-basalt compositions are used to create wear-resistant industrial and decorative floors. These compositions contain 80% basalt microfiber and 20% organic resins. Depending on the application, the flooring can be made using epoxy, epoxy-polyurethane, or polyurethane matrices.